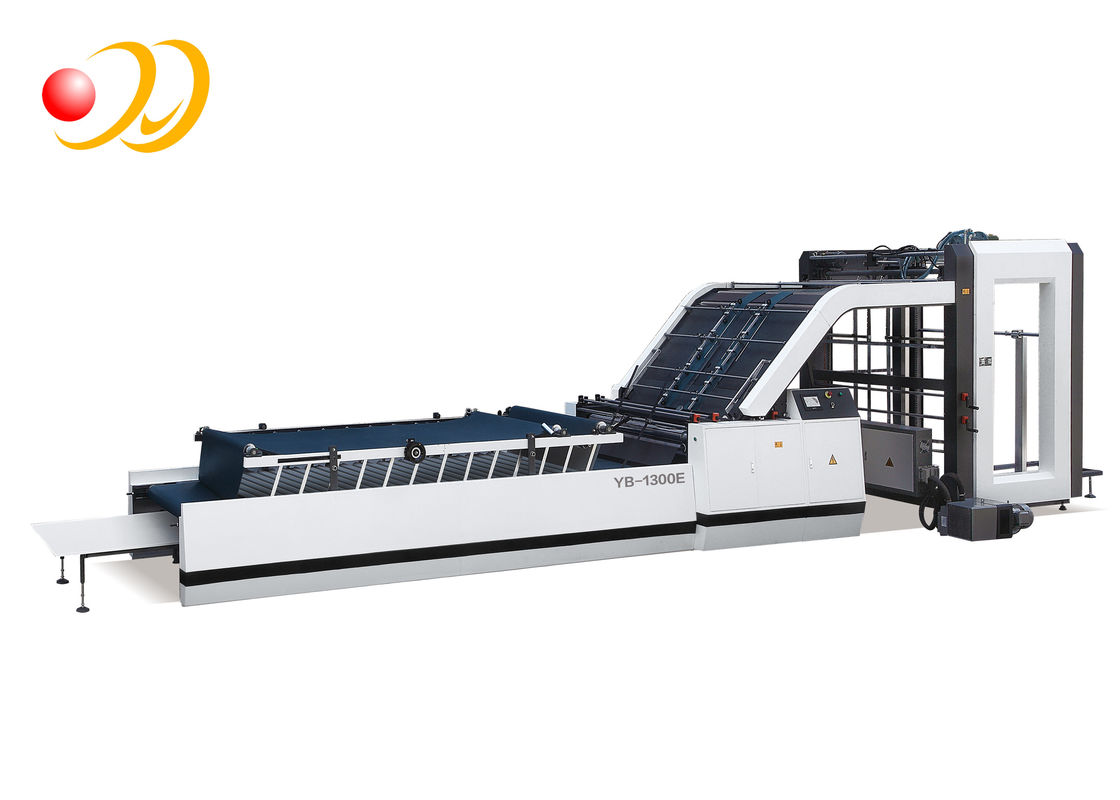

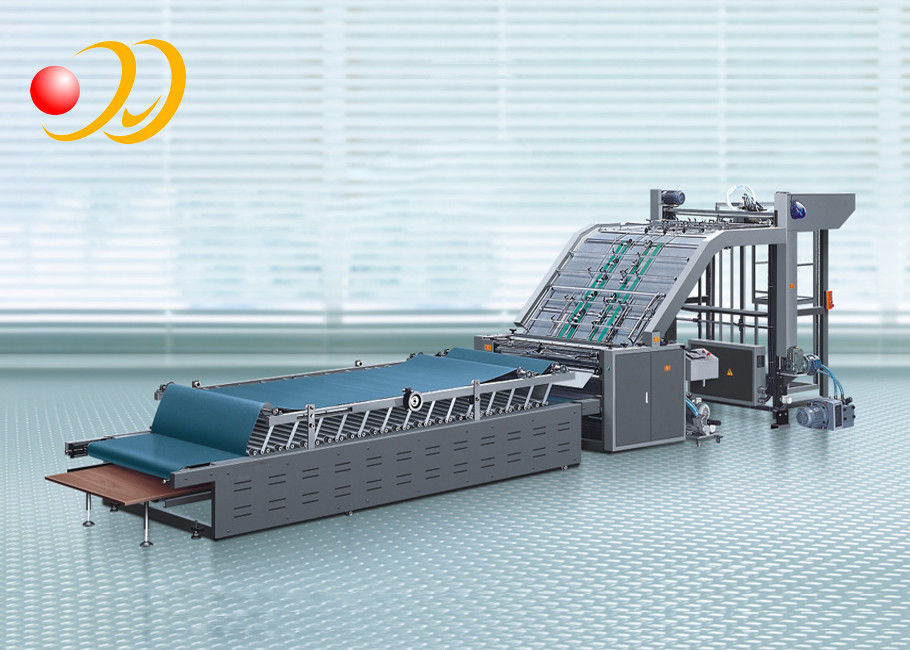

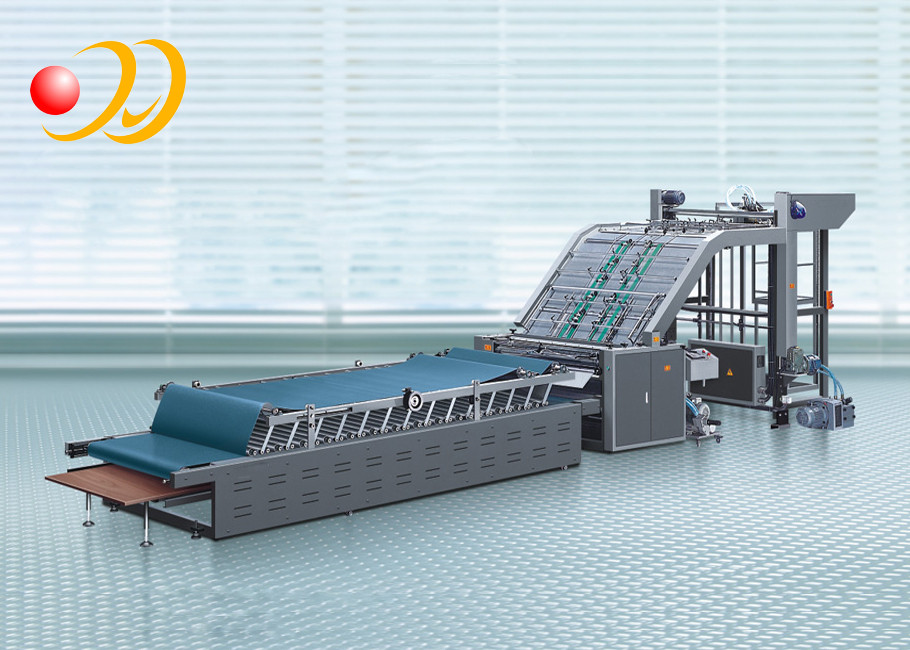

Fully Automatic Flute Laminating Machine With Vacuum Suction - Type Feeding System

Specifications :

|

Model

|

YB-1300E

|

YB-1450E

|

YB-1650E

|

|

Max Sheet size

|

1300*1250MM

|

1450*1250MM

|

1650*1450MM

|

|

Min Sheet size

|

400*400MM

|

400*400MM

|

400*400MM

|

|

Top sheet thickness

|

150-600GSM

|

150-600GSM

|

175-700GSM

|

|

Bottom sheet thickness

|

A.B.C.E.F corrugated paper, industrial cardboard

|

|

Machine speed

|

7000sheets/Hour

|

7000sheets/Hour

|

7000sheets/Hour

|

|

Fitting precision

|

±1mm

|

±1mm

|

±1mm

|

|

Measurement

|

11.5x2x2.4M

|

11.5x2.2x2.4M

|

11.5x2.4x2.4M

|

|

Machine weight

|

5000KG

|

5500KG

|

6000KG

|

|

Machine Power

|

10KW/380V

|

11KW/380V

|

12KW/380V

|

Introduction:

This machine is used for color top sheets and corrugated paper laminating, top paper adopt scale continuous paper feeding, unique front gauge positioning way to insure the bottom paper never exceed. Easy operation and maintenance.

Main Characteristics:

1. Advanced automatic tracking technology, according to the size of the paper automatically adjust the relevant parameters, so that the machine is always running in the best condition

2. Unique front gauge positioning system, accuracy and the bottom paper never exceed; top paper exceed adjustable

3. Equipped with high precision high speed automatic feeder, strengthening type paper feeding device, feeding smoothly

4. Equipped with high precision high speed automatic feeder, strengthening type paper feeding device, feeding smoothly

5. Using the principle of offset printing machine side gauge positioning, error correction for about top paper stack and feeding process

6. Bottom paper using suction automatic feeding, can adjust wind strength in the touch screen, and is equipped with a belt humidifying function

7. Standby stack table can pile paper under non-stop situation, along the rail into the elevator, high working efficiency

8. Imported electrical components, to ensure the stability of the circuit system, PLC tracking technology, automatic fault alarm

9. Fully automatic glue supplementary system, can automatically replenish the loss of the amount of glue, and cooperated with the glue recycling

10. Independent water tank control cycle, ensure the bottom paper back dry, at the same time cleaning up roller, glue receive tank and back glue tank

11. Single side adjustment of the roller pressure, and equipped with a dial gauge, the replacement of the bottom paper one-step-to-reach

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!